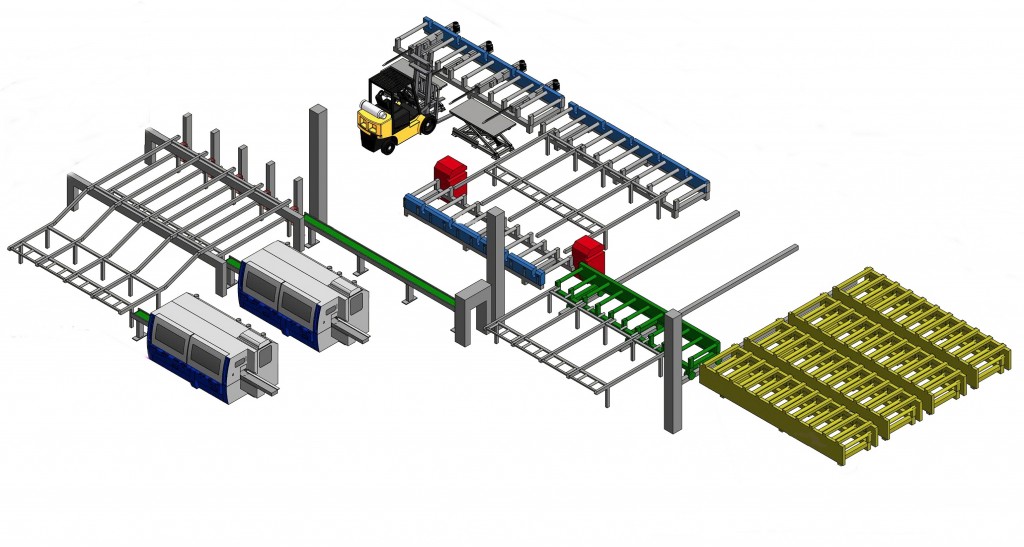

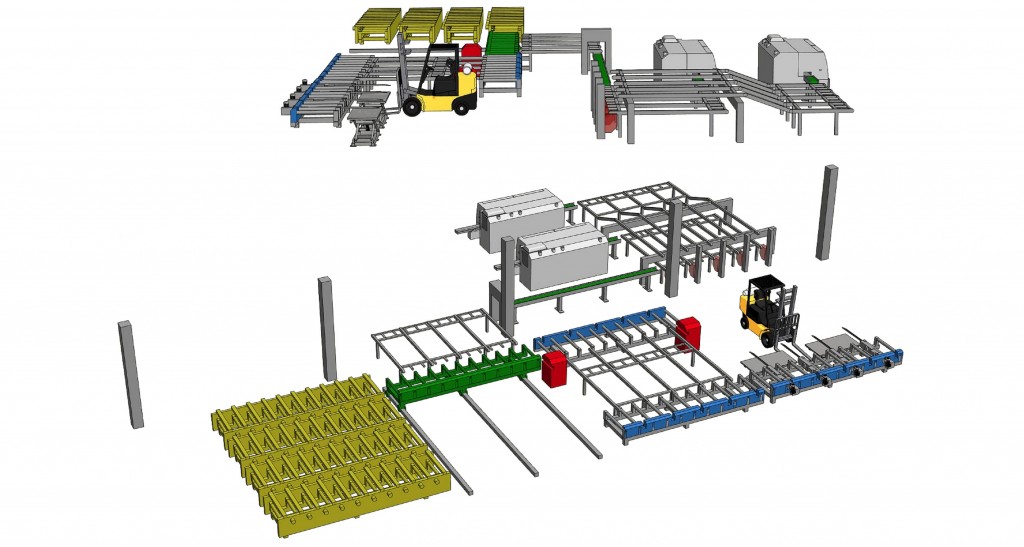

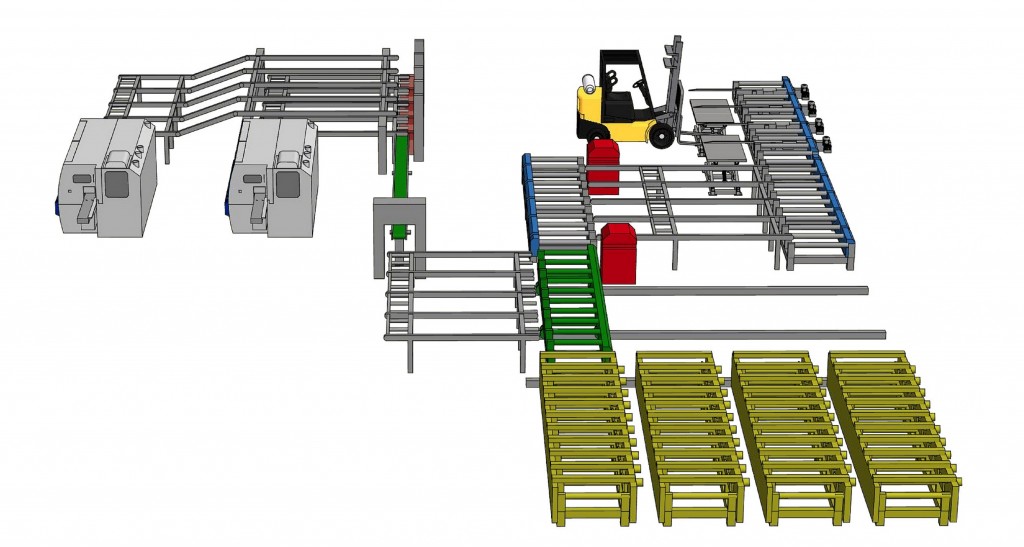

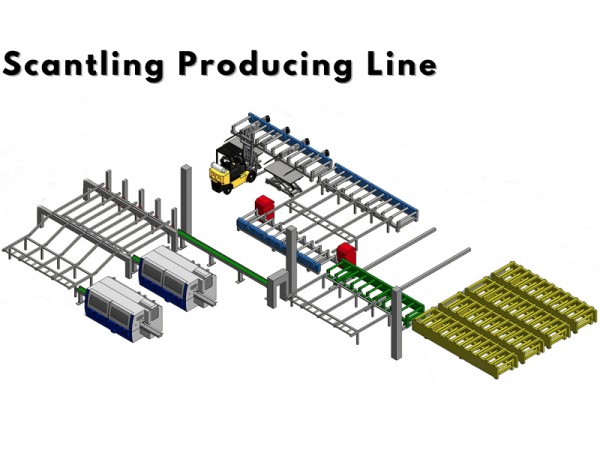

Scantling Producing Line

Process Description

1. 80m per minute high speed moulder

2. 2 Layers chain conveyor and switcher specified species and classify the timber then feed into glue applicator.

3. Glue applicator with feeding speed of the lamella 70-120m per minute

4. Auto flip mechanism and pusher feed the materials into roller conveyor cart.

5. Roller conveyor cart on switch rail system to separately feed the timber into every horizontal press. (Total 4 sets of horizontal press)

6. Timber both end cut by end saw system and fed into stacker.

Facts

1. Factory Size: Length x Width 40M x 24M = 960m2

2. Infeed size: Up to 6M long x 145mm width x 36mm thickness

3. Up to 40m3/shift 8 hour of scantlings.

4. Plant layout can be customized according to factory size.