LSP Series

Powerful cutterhead motor makes machine perfect for heavy-duty planning and meets high production requirements.

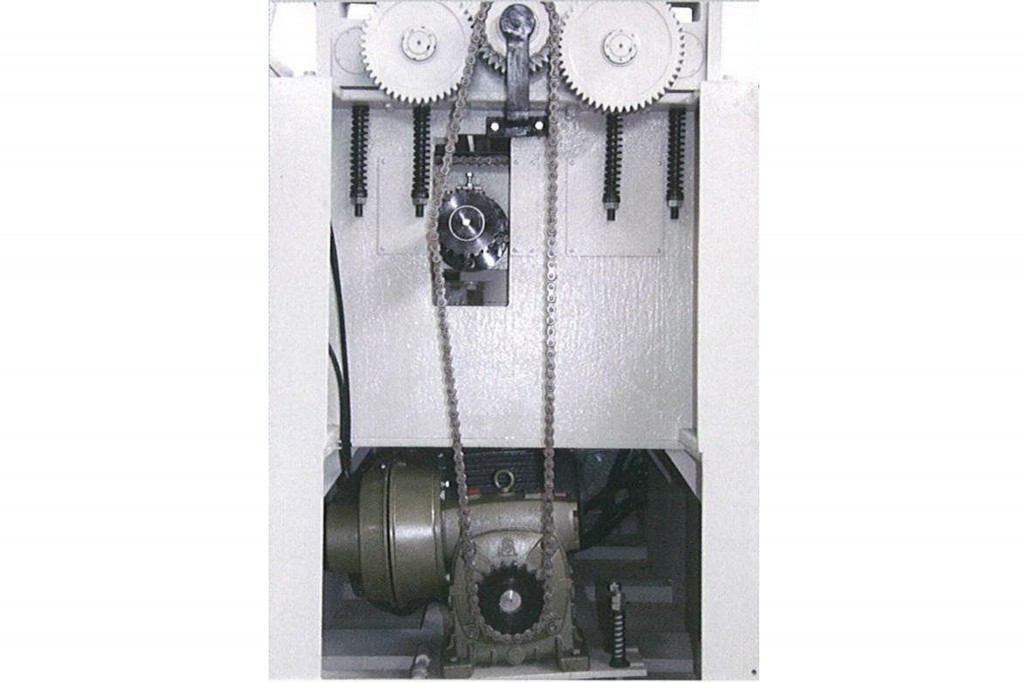

Variable speed driven by worm gear reducer (Feeding speed up to 25m/min).

Digital position controller for convenient thickness setting with keypad entry.

Ruggedly constructed throughout (cast iron and thick steel plate).

Spiral cutterhead provides high chip removal rate, superior surface finish and low noise level.

Anti-kickback fingers set at the infeed end provide additional safety for operator.

Corrugated sectional infeed rollers move independently for variable thickness feeding.

Powered table is precision ground and polished, with fast and convenient elevation setting for accurate thickness.

Power driven table rollers offer consistent & powerful feeding effect.

Additional emergency stop switch located on the back of the machine.

4 table rollers, 2 infeed rollers and 2 outfeed rollers run synchronously during machining and provide smooth operation even for heavy-duty use.