SK-610-DSP

Rugged cast iron ad plate steel fabrication provide long term dependability and low maintenance.

Infeed conveyor/carpet(spiked) allow precision jointing accuracy especially on warped or twisted lumber.

Computerized top cutterhead positioner is accurate ±0.05mm ensuring quick and accurate setup.

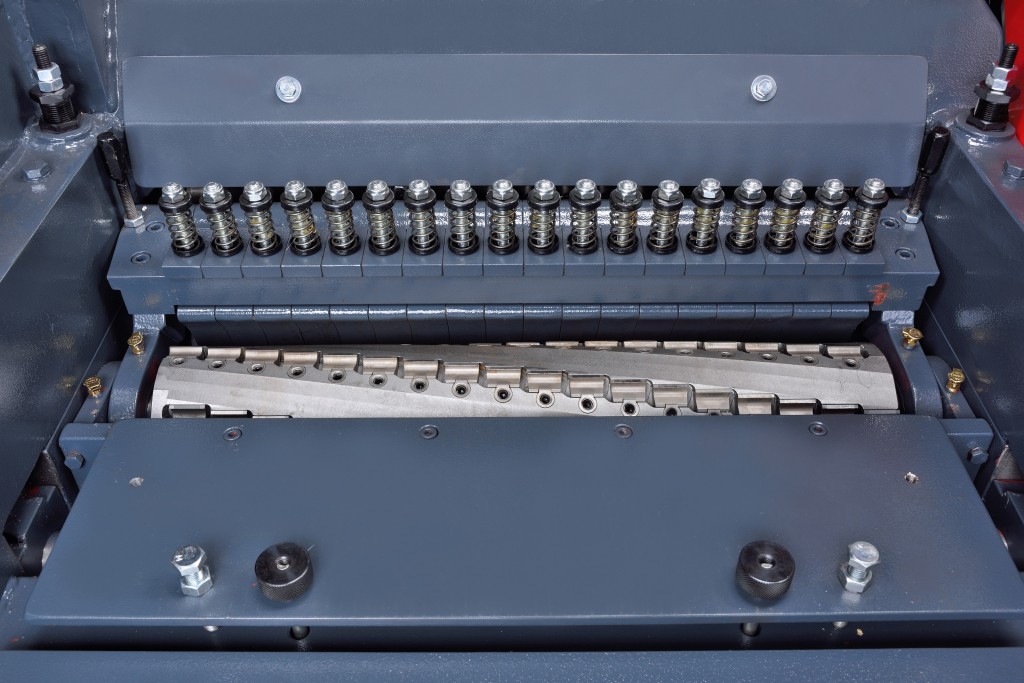

Cutterhead tooling technology guarantees low noise, reduced power requirements, minimal operations cost, and repetitive finish on the most difficult hardwoods.

Feed speeds up to 8-25M/min. allow the double side planer to meet high production demands.

Increased horsepower series surfacers provide greater capacity for stock removal while keeping finish at optimum levels.

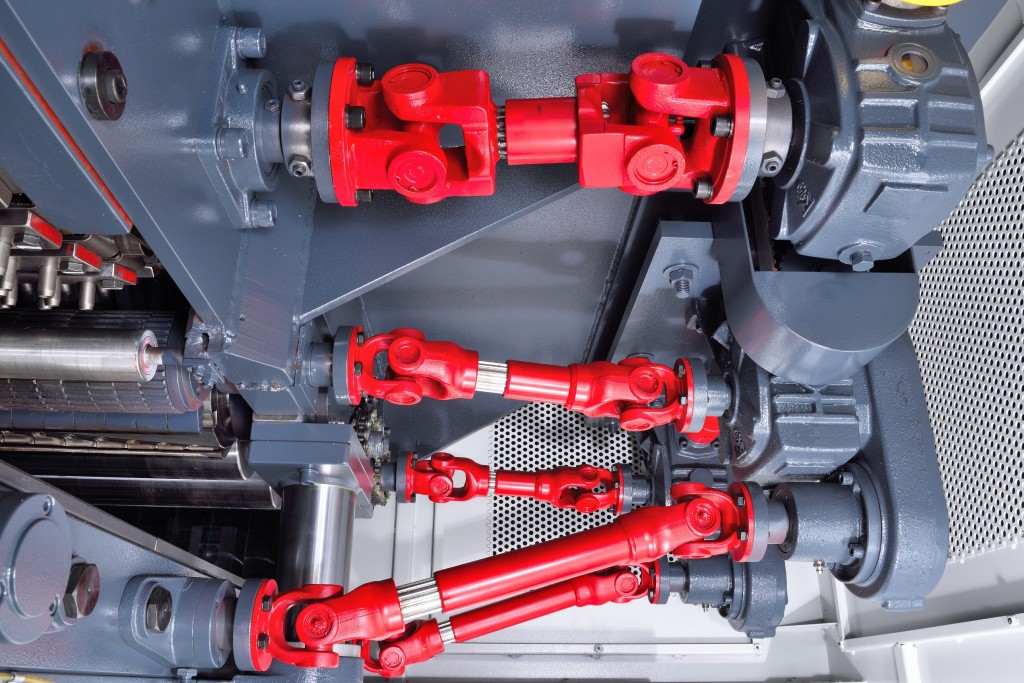

Patented lifting column system (synchronized transmission) guarantees repetitive setup and long-term dependability.

Patented universal drive transmission for feed groups and infeed carpet allows a maintenance free design vs. chain and constant finish.

Cutterheads are of solid steel construction, dynamically balanced and mated with precision pulleys.

Cutterheads are supported by “NSK” class 7 precision ball bearings and precision housings.

Chromed bed is standard on all double side planer yielding optimum wear.

New guards and skirts provide comprehensive operator safety.